Whatsapp us

Whatsapp us

Trong Trung tâm Tin tức, bạn sẽ tìm thấy nhiều lựa chọn tin tức thú vị và giàu thông tin về ECOPOWER.

Feb / 25, 2026

Ecopower to Exhibit at Three Major European Industry Events in 2026

Feb / 11, 2026

Ecopower Pre-Chinese New Year Shipment Rush: Ensuring Timely Delivery of All Products

Dec / 05, 2025

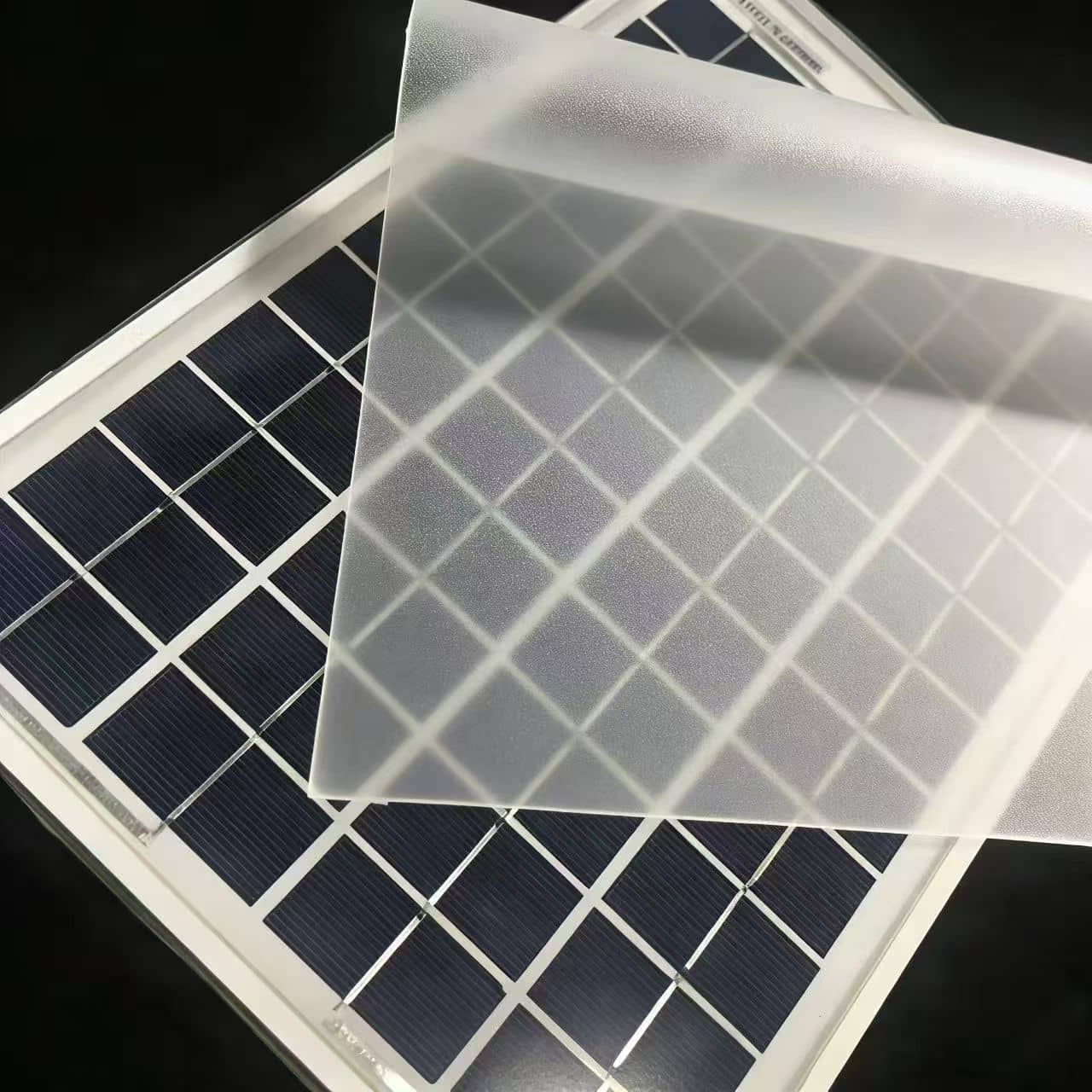

Potential Application of Ecopower Crosile®-7270 in Photovoltaic Encapsulation: Reinforcing Interfaces for Long-Term Reliability

Sep / 30, 2025

Ecopower Vinyltriisopropoxysilane (Crosile-173): Phụ gia chính cho độ bám dính vượt trội và độ bền vượt trội

Sep / 19, 2025

Ecopower tổ chức thành công buổi giới thiệu sản phẩm tại RubberTech 2025: Những đổi mới trong chất kết dính silane và nhựa thu hút sự chú ý của ngành công nghiệp toàn cầu

Aug / 21, 2025

Ecopower tại Triển lãm Keo dán và Chất bịt kín RubberTech & ASE CHINA 2025

Aug / 06, 2025

Ecopower trân trọng kính mời quý vị tham dự: Triển lãm quốc tế Trung tâm triển lãm quốc tế mới Thượng Hải lần thứ 23 (SNIEC)

Jun / 06, 2025

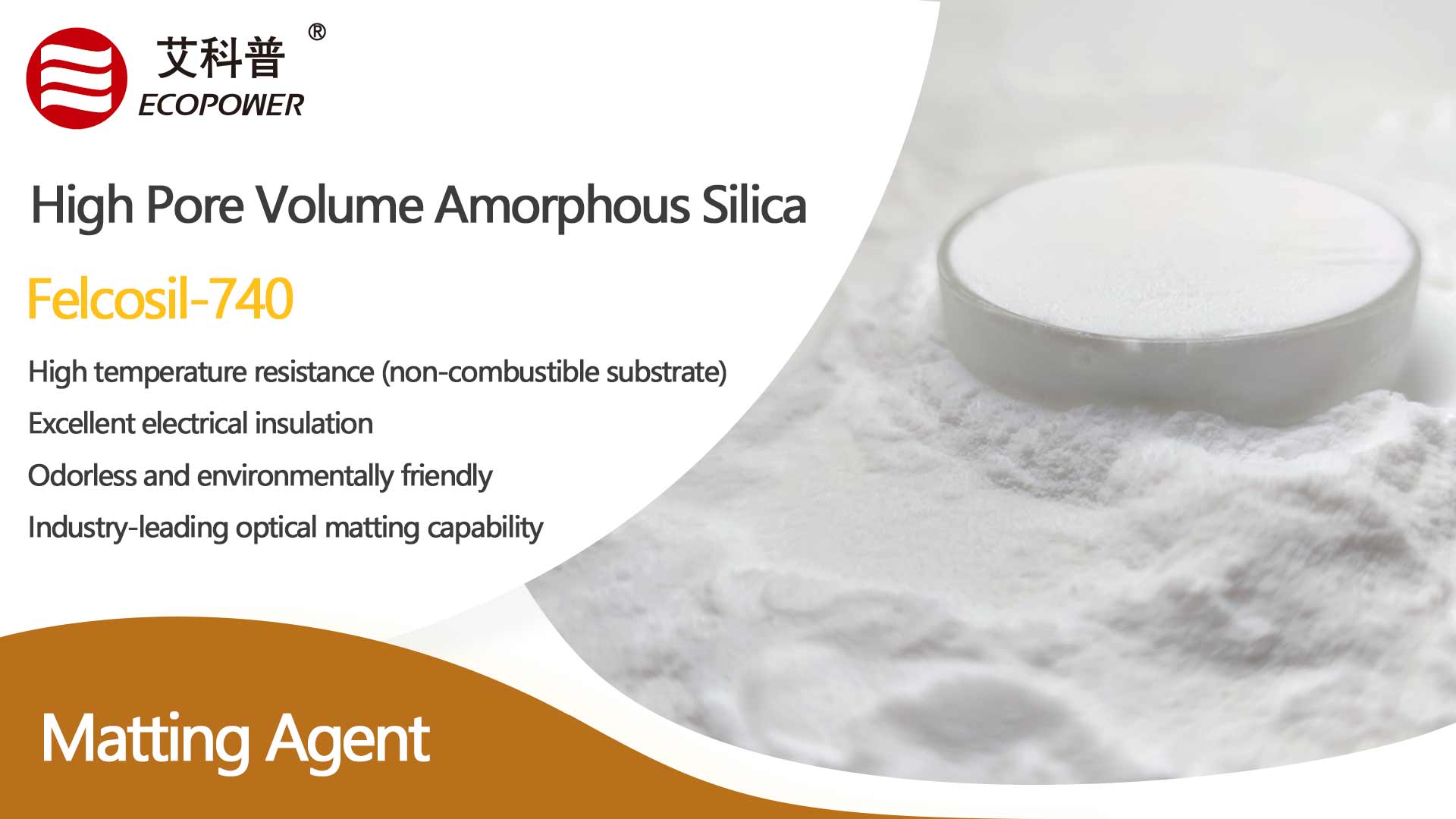

Ecopower Felcosil-740 Silica vô định hình: Chất độn thảm hiệu suất cao cho lớp phủ | Công nghệ Sol-Gel

May / 22, 2025

Công ty TNHH Vật liệu mới Ecopower (Yongxiu) đạt chứng nhận Ecovidas Silver

Apr / 29, 2025

Ưu điểm cốt lõi của nhựa HY-9100RM – Được thiết kế cho các ứng dụng đánh dấu đườngDi động/WeChat : +86 13802793127

WhatsApp : +8613802793127

E-mail : sales@ecopowerchem.com